Industrial Coffee Mill Guide: Boost Performance and High Quality

In the competitive landscape of coffee manufacturing, picking the ideal commercial coffee mill plays a critical duty in enhancing both effectiveness and product high quality. Comprehending the nuances of numerous mill kinds and vital features-- such as adjustable work settings and durable building-- can significantly influence the last taste profile of the coffee. In addition, the optimization of the grinding process, combined with thorough upkeep, is essential for sustaining performance gradually. As we check out these important components, it becomes apparent that the effects extend beyond mere equipment option, impacting overall company success in methods that require closer exam.

Understanding Grinder Kinds

When picking a commercial coffee grinder, recognizing the different types readily available is important for optimizing both taste extraction and operational effectiveness. The two primary kinds of grinders are blade grinders and burr mills.

Inevitably, selecting the ideal kind of grinder is indispensable to preserving top quality and effectiveness in coffee manufacturing, making it critical for companies to buy premium burr mills for optimum results.

Trick Features to Think About

Choosing an industrial coffee mill requires cautious factor to consider of several vital features that can significantly affect both efficiency and the general coffee experience. Among the primary elements to assess is the grinding system. Burr grinders are normally preferred over blade grinders, as they give a regular grind size, which is vital for ideal extraction and taste.

One more vital feature is the grinder's ability. Depending on the volume of coffee you need to process, pick a design that can manage your needs without compromising speed or top quality. Furthermore, think about the grind settings provided. A versatile mill with multiple setups enables you to tailor the work size to various brewing techniques, improving the coffee's taste account.

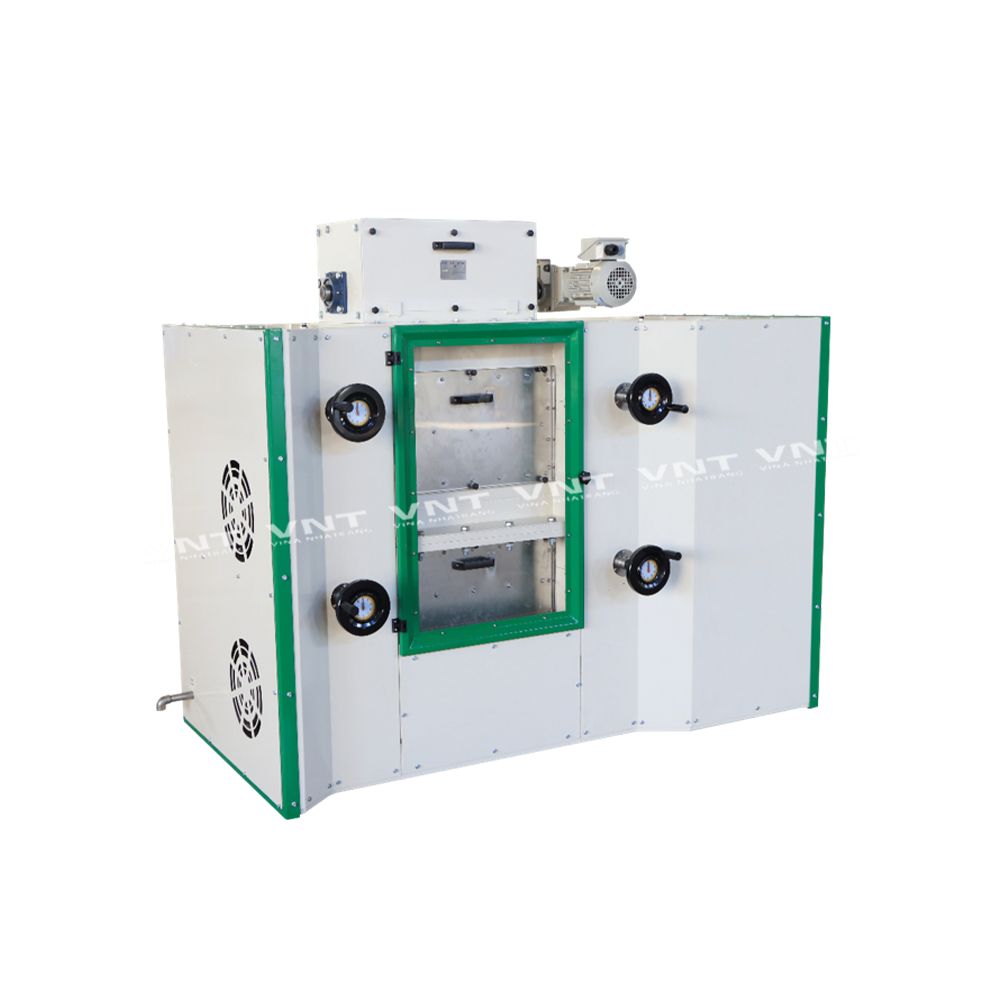

The building material also contributes in toughness and upkeep. Stainless-steel elements often provide durability and are easier to cleanse, which is vital for maintaining hygiene criteria. Finally, assess the mill's sound degree, particularly in a busy coffee shop or manufacturing atmosphere, where extreme sound can be turbulent. Purchasing a grinder that stabilizes these features can substantially enhance pop over to this site both functional efficiency and the top quality of the coffee offered.

Optimizing Grinding Process

To accomplish the most effective outcomes in coffee continue reading this preparation, optimizing the grinding process is important. The grind size significantly affects extraction, flavor, and total high quality of the brewed coffee. Various brewing methods call for certain work dimensions; for example, coffee demands a great work, while French press demands a coarse structure. Recognizing the partnership in between work dimension and developing technique is the very first step in optimization.

Additionally, checking the grinding rate can optimize the process. Slower grinding commonly produces much less heat, maintaining delicate tastes and aromas. Alternatively, quicker grinding might produce extreme warmth, negatively affecting the coffee's top quality.

Upkeep and Treatment Tips

Correct upkeep and treatment of industrial coffee grinders are crucial for ensuring optimal efficiency and longevity. Normal cleansing is the foundation of upkeep; residue build-up can affect flavor and grinding effectiveness. It is advisable to clean the mill after each usage, wiping down the outside and getting rid of any type of coffee grounds from the burrs.

In addition, check the grinding burrs for deterioration. Dull burrs can directory endanger grind consistency, so they need to be replaced as necessary. Industrial Coffee Grinder. Occasionally calibrating the grinder is additionally important, as this maintains the wanted grind dimension for different brewing approaches

Lubrication of relocating parts need to be done according to the manufacturer's requirements, as this minimizes friction and prolongs the life of the tools. It is necessary to make use of food-grade lubes to ensure safety and security and compliance with health guidelines.

Finally, maintain the grinder in a completely dry and secure environment to stop rust and rust. By sticking to these maintenance and treatment tips, operators can boost the efficiency of their industrial coffee mills while guaranteeing high-quality outcome and expanded operational life.

Roi Analysis

Assessing the roi (ROI) for commercial coffee grinders is important for organizations looking for to optimize their coffee production abilities. A thorough ROI analysis aids determine the monetary feasibility of purchasing premium mills, permitting organizations to weigh the preliminary expenses versus prospective gains.

Examine the purchase cost of the grinder, consisting of setup and any type of required modifications to existing facilities. High-performance grinders often lead to minimized grinding time and enhanced throughput, which can considerably boost efficiency.

In addition, think about the impact on item quality. Industrial Coffee Grinder. Superior mills yield an even more consistent work size, which can boost flavor accounts and client fulfillment, ultimately driving sales. By raising the high quality of the final item, businesses can validate greater pricing, bring about enhanced earnings

Conclusion

In recap, an industrial coffee grinder plays a crucial role in improving both performance and item quality within coffee production. By picking high-quality burr grinders furnished with important functions such as flexible work settings and resilient building and construction, businesses can make sure optimum taste extraction. Regular maintenance is important for maintaining mill efficiency and making best use of consumer satisfaction. Ultimately, the tactical investment in a reputable mill adds dramatically to boosted earnings and competition in the coffee sector.

In the affordable landscape of coffee manufacturing, choosing the best industrial coffee mill plays a crucial function in improving both efficiency and product top quality. The 2 main types of grinders are blade mills and burr grinders. Within the burr grinder group, there are level burr grinders and conical burr mills, each with its advantages. Burr grinders are generally favored over blade mills, as they offer a constant grind size, which is crucial for optimal removal and taste.

In summary, a commercial coffee mill plays a pivotal role in improving both performance and product quality within coffee manufacturing.